Profiling of three-layer solid wood panels

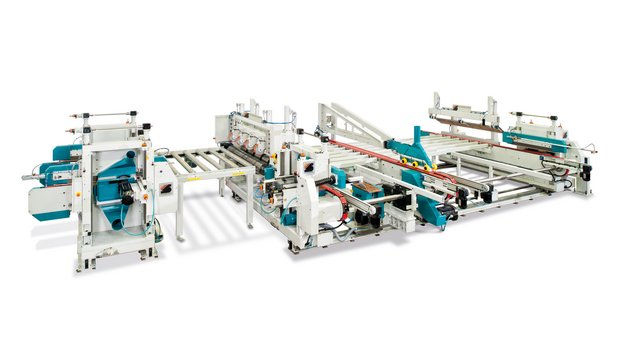

Fully automatic production line with a double end tenoner

At one of Europe's leading manufacturers of solid wood panels, a fully automatic production line from Schwabedissen is used for tongue and groove production, consisting of an automatic feeding system, a double end tenoner and an automatic stacking system.

The solid wood three-layer boards can be processed on both sides with tongue and groove. If the panels are to be processed on four sides with tongue and groove, the panels are transported through the production line a second time. For this purpose, the double-end profiler automatically adjusts itself to the dimension to be processed.