THE Double end tenoner

edge profiling at its best

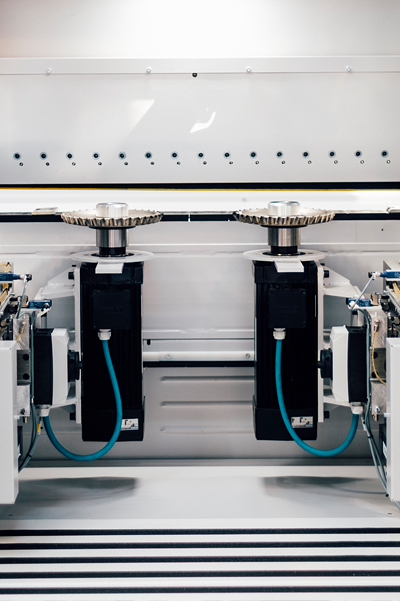

The most reliable double end tenoner technology

SCHWABEDISSEN profiling experience since 80 years

The Advantages of SCHWABEDISSEN

Double end tenoners

- high stability basic structure

- special guiding of the bottom chains

- perfect fixation of the workpiece by SCHWABEDISSEN top pressure system

- design of the machine for industrial applications

- double end tenoner experience since 80 years: plenty of references in various industries

Two designs responding your different needs

DOUBLE END TENONER Modul

The modern frame construction in top precision

The advantages- high fabrication precision of the raster modules

- high positioning speeds by means of linear guides

- upgradeable later on

- top pressure chains instead of belts

- operator friendly during tool change

Double end tenoner DAa

Proven in the industry since decades

The advantages- Tailormade system solutions

- Important machine elements in cast ironing

- Top pressure chains instead of belts

- Efficient central dust extraction

80 Years double end tenoner

Since approx. 80 years our double end tenoners are used for panel edge processing in longitudinal and cross direction.

SCHWABEDISSEN has numerous references for double end tenoners in the wood industry (solid woods, particle board) as well as plastics, mineral (gypsum or cement), metallic and bonded material industry.

SCHWABEDISSEN has numerous references for double end tenoners in the wood industry (solid woods, particle board) as well as plastics, mineral (gypsum or cement), metallic and bonded material industry.

Double end tenoners are successfully used for trimming and sizing single panels as well as profiling in automatic production lines, too.

Double end tenoners work simoultaneously on both panel sides during the material is transported along the processing motors by means of special chain conveyors. Therefore these machines achieve a very high output combined with high processing precsion and accuracy.

The panel industry like particle board or OSB producers use the double end tenoner for profiling tongue and groove boards. Further typical edge processing work is trimming, profiling, grooving, processing of rebates, corners and different contours.

Generally SCHWABEDISSEN double end tenoners are able to work only single sided, e. g. in case of very narrow workpieces. In addition to individual machines we are able to supply the feeding and stacking devices, too.

Applications and References

Innovative concepts for your material

WOOD-BASED PANELS

PB, MDF, OSB, plywood, solid wood

more info

GYPSUM/FIBER/CEMENT

Plasterboard, gypsum fibre, mineral fibre, fibre cement, cement bonded boards

more info

FURNITURE PARTS

Solid wood, rear panels, drawer parts

more info

COMPOSITE MATERIAL

HPL, compressed laminated wood, Aluminium/plastics

more info

CONCRETE FORMWORK

Formwork beams and shuttering panels

more info

WOODEN DOORS

CNC processing center / double end tenoner

more info

INSULATING MATERIAL

Carton pressed boards

more info

WALL PANELS/PARQUET

Cross processing with double end tenoner more info

WOODEN WINDOWS

Profiling of window frames with single sided tenoner

more info

SHAPED PARTS

5-axis processing with robot head

more info