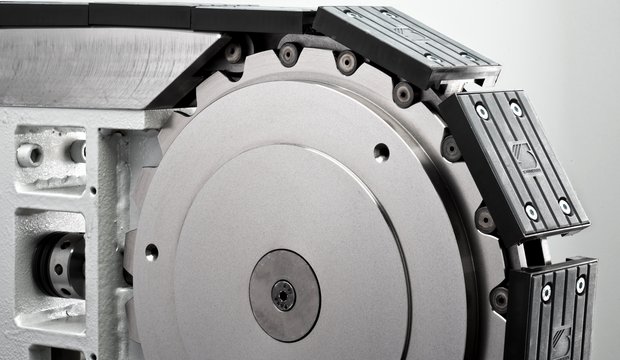

SCHWABEDISSEN double end tenoners DAa are based on a sturdy design with vibration-free construction components, being the prerequisite for stability and precision.

Very important parts are made from cast ironing, e. g.

- machine columns

- chain tracks

- chain wheels

- motor supports

- etc.

These parts are mounted in a frame construction and built an enclosed, torsion resistant and extremely sturdy unit on the machine beds.