Saw for single panels

Longitudinal saw for inline applications

- for trimming and longitudinal cutting of wood based panels like chipboards, MDF, OSB, blockboards, etc.

- cutting single panels from below or, if required, from above

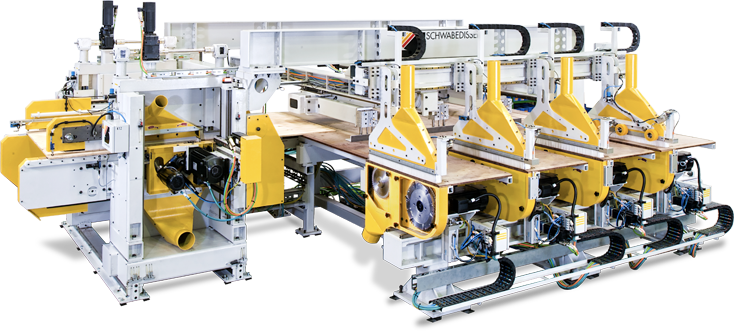

- saw Type LS with transport- and pressure-rollers before and after trimming- and cutting saws for guide and transport of the panel material

- double end tenoner Type DAa with bottom transport chains and top pressure chains for high processing precision

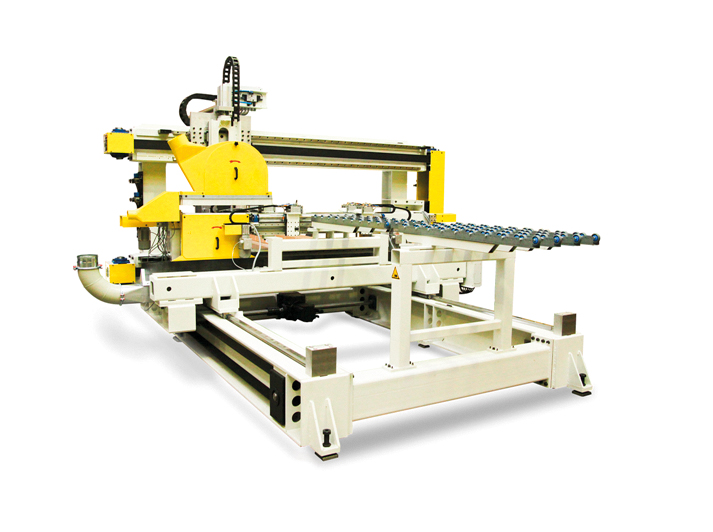

Cross cut saw QS for stop and go panel transport

- for trimming and cross cutting of wood based panels like chipboards, MDF, OSB, blockboards, etc.

- the panels need to be stopped and aligned before cutting

- cutting of single panels from below or, if required, from above

- with pressure beam in front and behind the saw cut

Cross cut saw F100 for inline applications

- a pusher takes over the panels at the longitudinally trimmed edge and pushs them through the stationary cross cutting saws

- cross trimming and cutting of panels with saw motors from below

Cross cut saw F47

- Trimming and sawing of panels from above by cross cut gantries QS

- the gantries QS are either fix or move to position according to panel dimension

- the panel material will be positioned by an integrated roller conveyor

Cross cut saw for endless panel material

Diagonal saw

Since decades diagonal saws are installed behind continuous press systems for cross cutting continuously produced panel material to single master panels.

This process requires automatic cutting equipment with a high degree of reliability and accuracy, to avoid interrupting the production process.

The gantry is positioned in a certain angle to the transport direction of the material.

The PLC controls and modifies the necessary speed of the saw carriage depending on the transport speed of the material

This type of equipment is used for the cutting to length of continuously pressed chipboard and fibreboards as well as endlessly laminated individual board lengths (worktops).

Optional: Length trimming saws are set up in front of the diagonal saws for trimming the longitudinal edges of the panels. This system can therefore produce panels trimmed on all four sides and sized to any customer requirements.

Flying cut-off saw

This cross cut saw is installed behind continuously produced board material, e. g. behind double belt press systems. Further the machine can be used for endlessly foamed or extruded plastic sheets (Polyurethane or polystyrene insulating panels) and continuous lengths of sandwich board (insulating panels).

During cross cutting the saw beam travels with the material. After having cut the material the beam travels back to its start position.

With this saw design it is possible to fix the board material during cutting by means of clamps from the side or a pressure beam from the top.

The material can have the following specifications:

- width: 900 - 1.250 mm

- thickness: 40 – 200 mm

Applications and References

Innovative concepts for your material

WOOD-BASED PANELS

PB, MDF, OSB, plywood, solid wood

more info

GYPSUM/FIBER/CEMENT

Plasterboard, gypsum fibre, mineral fibre, fibre cement, cement bonded boards

more info

FURNITURE PARTS

Solid wood, rear panels, drawer parts

more info

COMPOSITE MATERIAL

HPL, compressed laminated wood, Aluminium/plastics

more info

CONCRETE FORMWORK

Formwork beams and shuttering panels

more info

WOODEN DOORS

CNC processing center / double end tenoner

more info

INSULATING MATERIAL

Carton pressed boards

more info

WALL PANELS/PARQUET

Cross processing with double end tenoner more info

WOODEN WINDOWS

Profiling of window frames with single sided tenoner

more info

SHAPED PARTS

5-axis processing with robot head

more info