Trimming of heavy cement fibre boards

The European market leader in cement fibre boards is investing in another production line for the manufacture of cement fibre boards in one of its plants.

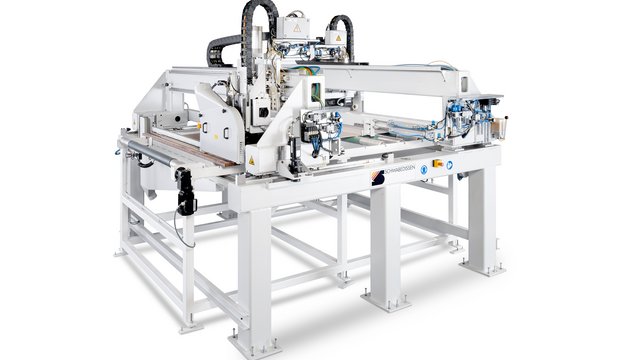

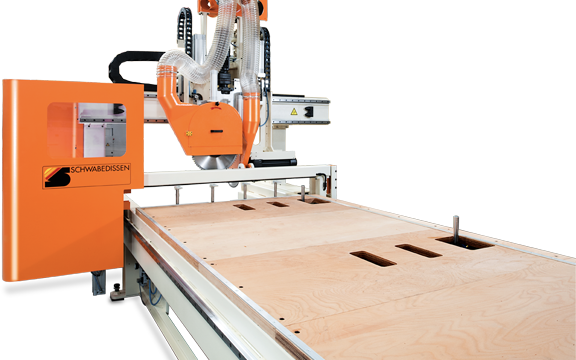

Two SCHWABEDISSEN double-end tenoners for longitudinal and cross processing are used for trimming the boards.

Due to the large thickness spectrum of 9 - 110 mm and a maximum panel density of 1,500 kg/m3, the panels weigh up to 600 kg.

Very large cutting motors are used for this processing.

For user-friendly adjustment, the motors are positioned fully automatically in height. The system is equipped with the latest control generation from Siemens.