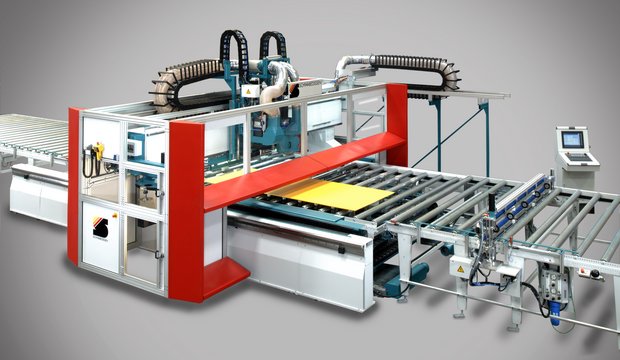

Double end tenoner for timber formwork beams

Milling and drilling of the cross edges of timber formwork beamsThe double end tenoner for processing the cross edges of formwork beams is working discontinuously. The material is transported stepwise to the processing positions.

The ends of the material are milled in the double end tenoner.

In the next step the ends are drilled automatically.

Material length: max. 5.900 mm

Material width: max. 200 mm

Capacity: 5 pieces/min.